Checkweigher vs Weight Grading Machine

(Key Differences and How to Choose the Right Solution)

Introduction

In food processing industries, both checkweighers and weight grading machines are widely used for weight control. However, many processors are unclear about the differences between these two systems.

Choosing the wrong equipment can result in inefficient production, unnecessary investment, or unmet processing requirements. This article explains the key differences between a checkweigher and a weight grading machine, and helps processors select the right solution for their application.

1. What Is a Checkweigher?

A checkweigher is designed to verify whether a product’s weight falls within a predefined tolerance range.

Main functions of a checkweigher:

• Detect underweight or overweight products

• Ensure compliance with packaging regulations

• Automatically reject non-conforming items

Checkweighers are commonly used in:

• Packaging lines

• Quality control processes

• Final inspection before shipment

Their primary purpose is weight verification, not classification.

2. What Is a Weight Grading Machine?

A weight grading machine is designed to classify products into multiple weight categories.

Main functions of a weight grading machine:

• Measure product weight dynamically

• Sort products into different weight grades

• Support pricing, portion control, and export standards

Weight grading machines are widely used in:

• Poultry processing plants

• Fish and shrimp processing

• Meat and seafood grading lines

Their primary purpose is weight-based sorting and classification.

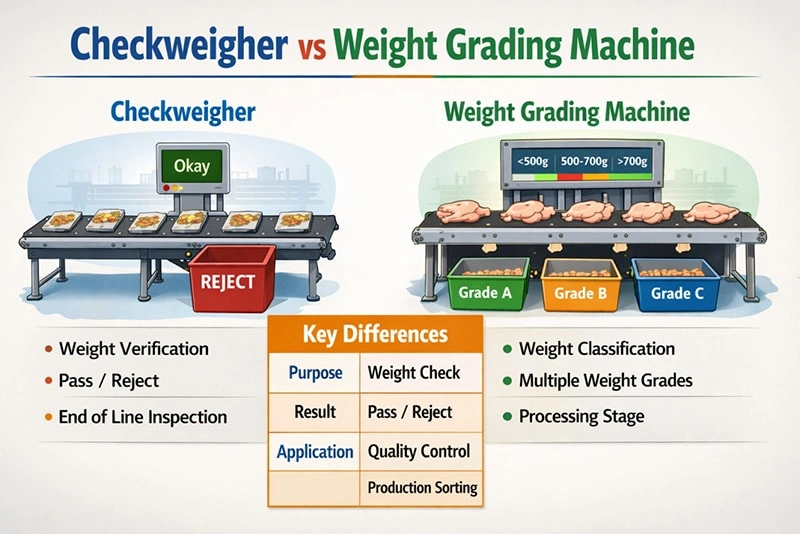

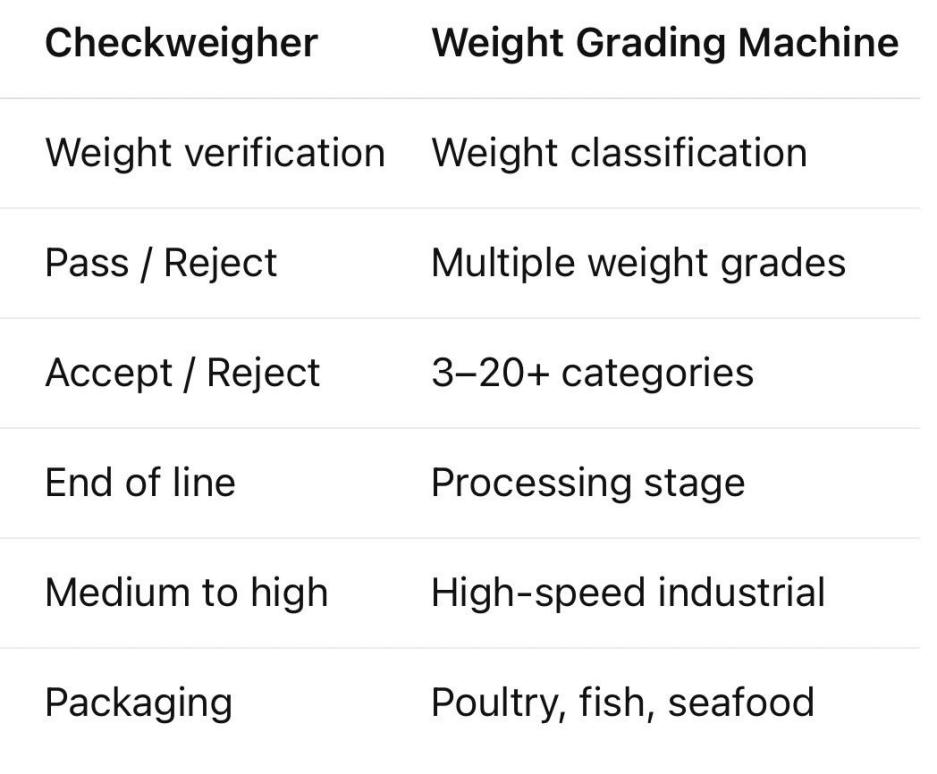

3. Key Differences Between Checkweigher and Weight Grading Machine

4. When Should You Choose a Checkweigher?

A checkweigher is suitable if your main goal is:

• Ensuring package weight compliance

• Detecting underweight or overweight products

• Performing final quality checks

Typical scenarios:

• Packaged food production

• Export compliance inspection

• Retail packaging lines

In these cases, weight classification is not required.

5. When Should You Choose a Weight Grading Machine?

A weight grading machine is the right choice if you need to:

• Sort products into different weight categories

• Improve pricing accuracy and product consistency

• Reduce manual grading labor

• Meet export or customer-specific weight standards

Typical scenarios:

• Poultry processing plants

• Fish and shrimp export processing

• High-volume food processing lines

For Southeast Asia and Middle East markets, weight grading machines are essential for export-oriented production.

6. Can Checkweighers and Weight Grading Machines Be Used Together?

Yes. In many modern processing plants, both systems are used in the same production line.

Example:

• Weight grading machine: Sort products into weight categories during processing

• Checkweigher: Verify final package weight before shipment

This combination improves both production efficiency and quality control.

7. How to Choose the Right Supplier

Regardless of which system you choose, a professional supplier should offer:

• Application-specific solutions

• Stable and accurate weighing technology

• Custom integration capability

• Reliable after-sales support

For processors handling poultry and aquatic products, industry experience is especially important.

Conclusion

The key difference between a checkweigher and a weight grading machine lies in their purpose. A checkweigher focuses on weight verification, while a weight grading machine focuses on weight classification.

Understanding this difference helps processors invest in the right equipment, improve production efficiency, and meet market requirements more effectively.

Get a Quote

*RequiredPlanning to upgrade your weight sorting system?

Share your application details and our team will recommend a suitable solution.