Manual weighing combination, material matching difficulty, low production efficiency, high labor costs

Under the same output, the labor cost is much larger than the equipment cost.

Ordinary equipment has low precision and speed, low safety coefficient, and cannot really realize cost reduction and efficiency.

The OYDE intelligent weight machine is specifically designed for precise weight sorting of pre-prepared foods and is suitable for a wide range of products, including ready-to-eat meals, frozen processed dishes, cooked meat packaging, pre-cut ingredients, frozen dumplings and other quick-frozen foods. Equipped with advanced sensors, it can achieve accurate weight sorting without damaging delicate packaging or affecting the integrity, taste and texture of the food itself, fully meeting the strict quality requirements of pre-prepared food processing.

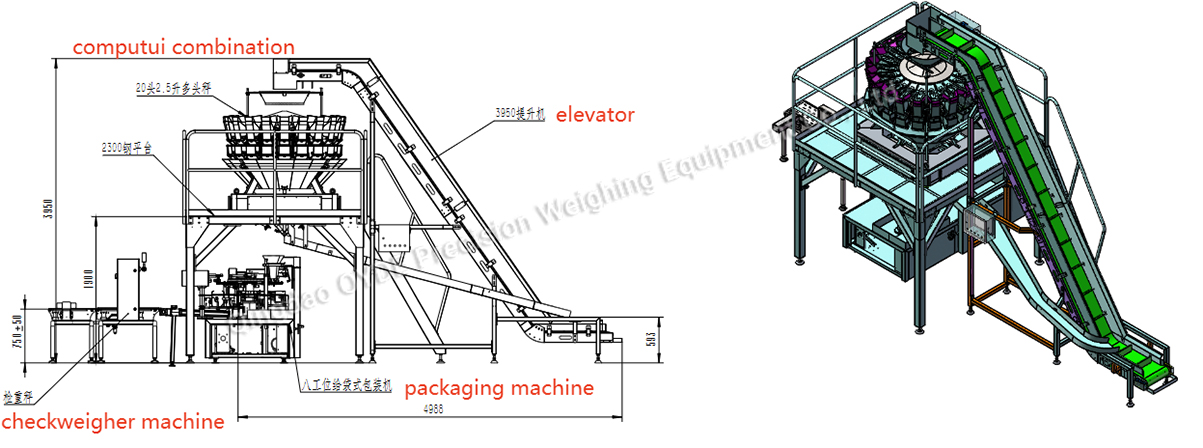

Steps:Feeding,→quantitative weighing→packaging→checking-weight→fforeign substance examination→boxing→palletizing

Its robust, waterproof stainless steel build complies with rigorous food safety and hygiene regulations, making it ideally suited for the sterile, high-cleanliness processing lines of prepared food enterprises. Driven by an intelligent weighing system, the machine not only boosts operational efficiency and minimizes product waste during high-volume production runs, but also provides consistent, steady grading performance to ensure standardized portioning and packaging—empowering prepared food businesses to optimize workflows and enhance market competitiveness.

Considering the unique characteristics of prepared foods—such as the generation of crumbs and the tendency for liquid adhesion when temperatures rise—our company has engineered specialized coatings for equipment tailored to the prepared food industry. These coatings not only meet stringent food safety and health standards but also ensure the stable, long-term operation of the equipment. Coupled with the advanced intelligent weighing technology and intelligent weighing system, the equipment supports accurate weight reduction and combination packaging processes seamlessly. In turn, this thoughtful design optimizes production efficiency for prepared food enterprises while upholding the highest quality and hygiene benchmarks, providing a reliable and professional solution for the industry’s unique processing needs.